- – High quality austenitic stainless steel inside

and outside (except for galvanised back

panel).

– 40 kg/m3

injected polyurethane isolation.

60 mm thick side walls, while the ceiling is

40 mm thick with a 50 mm worktop on it to

make a total 90 mm thickness.

– Copper piping and aluminium flaps

evaporator.

– HACCP system that keeps running logs.

– Digital display for electronic and digital

control of temperature and defrosting.

– The controls are integrated in the front

panel for a better protection against dirt.

IPX5 compliant, the controls are protected

against water splash and jets.

– Acoustic and visual alarm connected

to three sensors at strategic spots.

They provide a total control and block the

compressor in case of dirt or failure. - – Opened door delay alarm.

– Easier loading and unloading thanks to its

door self-closing and stay open features.

– Removable and height adjustable plastic

covered steel shelves for easy cleaning

(GN1/1 size).

– Equipment per door: 1 GN 1/1 grid and 2

sets of height adjustable tray slides.

– Built-in drainage to get rid of waste liquids

inside the unit.

– Embedded bottom and curved panels inside

for easy cleaning and maintenance.

– Interior LED lighting (only for models with

glass doors).

– Height adjustable stainless steel legs.

– 10 cm high splashback.

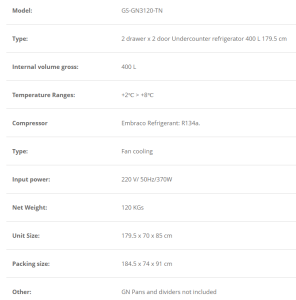

– Working temperature: from -2 ºC to +8 ºC

(refrigerators) and from -18 ºC to -22 ºC

(freezers).

– Ambient temperature: 43 ºC (*)

– Climatic class 4.

Options:

– Castor kit (factory assembly).

– Without splashback.

– Without worktop.

– Different drawer models.

– Left side cooling unit.

– Panoramic door opening.

– Stainless steel back.

– Granite worktops.

– Heated door frame to

avoid condensation in high humidity

environments.

– Lock (standard in glass doors).

Description

Leave a reply