– Unloading of oil from the well by means of

a robust and reliable ball valve, resistant to

high temperatures.

– With individual lids for each well.

– High temperature enamelled cast iron flue

protector.

– Access to the components from the front.

– Machines with IPX5 grade water protection.

MODEL WITH DIGITAL CONTROL:

– High-precision electronic oil temperature

control between 60-200ºC, +/- 1ºC.

– Setpoint temperature display with an

indicator to show when temperature has

been reached.

– Time control card per basket with audible

alarm.

– “Melting” programme.

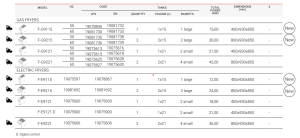

SUPPLIED BASKETS

– 21-litre fryers: 2 small bas-kets per well

(130 x 330 x 130 mm).

– 15-litre fryers: 1 small basket per well

(250 x 280 x 100 mm).

– Surface tops manufactured in 2 mm thick AISI-304 stainless

steel.

– Laser-cut joints, automatic welding and polishes. Screws

hidden from view.

– Wells stamped into the surface top.

– Cold zone in the lower part of the well, which helps to

maintain the quality and characteristics of the oil in use for

longer.

– Thermostatic temperature control between 60 and 200 °C.

– Gas models with three longitudinal heating tubes integrated

into the well.

– High efficiency gas burners.

– Electric models with AISI-304 stainless steel heating

elements located inside the well, which can be swivelled by

more than 90° for perfect cleaning.

– High-power machines which heat up very fast and with a

high power:litre ratio (up to 1.00 kW/litre in gas models).

– Ignition by spark train for the gas models.

– Safety thermostat in all models.

Description

Leave a reply